Transfer Orders

Integration of availability indicators streamlines transfer order process, providing quick insights into item availability. Users can make informed decisions directly within the interface, preventing delays, stockouts, or overstock situations, thus improving overall supply chain efficiency.

None / White: the transfer order line is completely shipped. In the following example there is nothing to ship:

None / White: the transfer order line is completely shipped. In the following example there is nothing to ship:

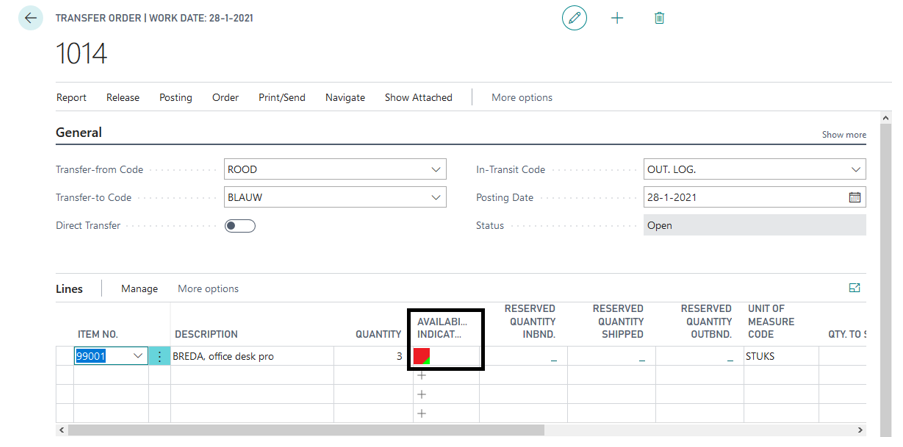

Red/Green: Sum of all demand lines (Qty. on Sales Order + Qty. on Purch. Return + Qty. on Component Lines + Qty. on Asm. Component + Trans. Ord. Shipment (Qty.) + Qty. on Service Order) is bigger than the Inventory, but there is some inventory available to ship and not enough available in the supply lines (Qty. on Purch. Order + Qty. on Assembly Order + Trans. Ord. Receipt (Qty.) + Qty. on Sales Return + Qty. on Prod. Order) to fulfill in the needs. See the example below:

Red/Green: Sum of all demand lines (Qty. on Sales Order + Qty. on Purch. Return + Qty. on Component Lines + Qty. on Asm. Component + Trans. Ord. Shipment (Qty.) + Qty. on Service Order) is bigger than the Inventory, but there is some inventory available to ship and not enough available in the supply lines (Qty. on Purch. Order + Qty. on Assembly Order + Trans. Ord. Receipt (Qty.) + Qty. on Sales Return + Qty. on Prod. Order) to fulfill in the needs. See the example below:

Green: the quantity on stock is sufficient for the open demand lines. The calculation for the green indicator is: Sum of all demand lines (Qty. on Sales Order + Qty. on Purch. Return + Qty. on Component Lines + Qty. on Asm. Component + Trans. Ord. Shipment (Qty.) + Qty. on Service Order) is smaller than the Inventory. In the example below the inventory is sufficient for shipping the transfer order line:

Green: the quantity on stock is sufficient for the open demand lines. The calculation for the green indicator is: Sum of all demand lines (Qty. on Sales Order + Qty. on Purch. Return + Qty. on Component Lines + Qty. on Asm. Component + Trans. Ord. Shipment (Qty.) + Qty. on Service Order) is smaller than the Inventory. In the example below the inventory is sufficient for shipping the transfer order line:

Orange: there is no inventory but the sum of the supply lines (Qty. on Purch. Order + Qty. on Assembly Order + Trans. Ord. Receipt (Qty.) + Qty. on Sales Return + Qty. on Prod. Order) is similar to or bigger than the quantity of the demand lines. See the example below:

Orange: there is no inventory but the sum of the supply lines (Qty. on Purch. Order + Qty. on Assembly Order + Trans. Ord. Receipt (Qty.) + Qty. on Sales Return + Qty. on Prod. Order) is similar to or bigger than the quantity of the demand lines. See the example below:

Red: there is no inventory to fulfill the need in demand lines. There are also no supply lines to fulfill in this needs. See the example below:

Red: there is no inventory to fulfill the need in demand lines. There are also no supply lines to fulfill in this needs. See the example below:

Orange/Green: Sum of all demand lines (Qty. on Sales Order + Qty. on Purch. Return + Qty. on Component Lines + Qty. on Asm. Component + Trans. Ord. Shipment (Qty.) + Qty. on Service Order) is bigger than the Inventory, but there is some inventory available to ship and enough available in the supply lines (Qty. on Purch. Order + Qty. on Assembly Order + Trans. Ord. Receipt (Qty.) + Qty. on Sales Return + Qty. on Prod. Order) to fulfill in the needs for all the demand lines. See the example below:

Orange/Green: Sum of all demand lines (Qty. on Sales Order + Qty. on Purch. Return + Qty. on Component Lines + Qty. on Asm. Component + Trans. Ord. Shipment (Qty.) + Qty. on Service Order) is bigger than the Inventory, but there is some inventory available to ship and enough available in the supply lines (Qty. on Purch. Order + Qty. on Assembly Order + Trans. Ord. Receipt (Qty.) + Qty. on Sales Return + Qty. on Prod. Order) to fulfill in the needs for all the demand lines. See the example below: